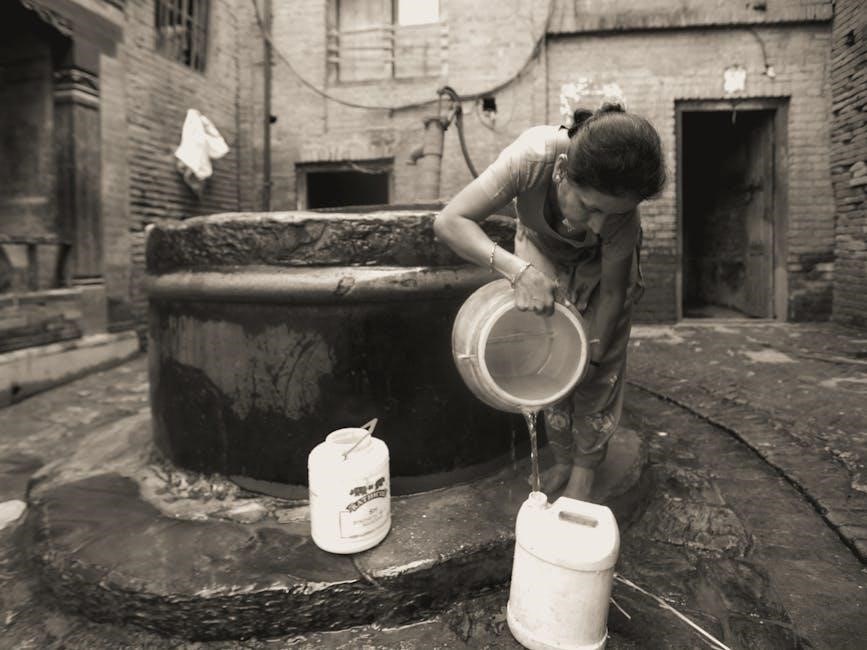

manual water pump for well

Manual water pumps are human-powered devices that extract water from wells using a piston and cylinder mechanism. Ideal for shallow or deep wells, they offer a reliable, cost-effective, and eco-friendly water supply solution without electricity, perfect for off-grid and emergency situations.

Overview of Manual Water Pumps

A manual water pump is a device designed to extract water from a well using human effort. It operates through a simple mechanism involving a piston, cylinder, and handle. When the handle is moved up and down, the piston creates suction, drawing water from the well and pushing it through a spout or hose. These pumps are versatile, suitable for both shallow and deep wells, depending on their design. They are often portable, making them ideal for various applications, including emergency water supply, off-grid living, and small-scale irrigation.

Manual pumps are durable and require minimal maintenance, relying on basic mechanical components rather than electricity. They are environmentally friendly, as they do not consume energy or produce emissions. Their simplicity and reliability make them a practical solution for accessing water in remote or resource-limited areas.

Importance of Manual Water Pumps for Wells

Manual water pumps are essential for accessing water from wells, especially in areas with limited electricity or during power outages. They provide a reliable and sustainable way to extract water for drinking, irrigation, and household needs. These pumps are crucial for emergency preparedness, ensuring water availability when modern systems fail. Their simplicity and durability make them a cost-effective solution for long-term water supply. Additionally, manual pumps promote self-sufficiency and reduce reliance on external energy sources, making them environmentally friendly. They are particularly valuable in remote or off-grid locations, where they serve as a lifeline for communities and individuals. By offering a practical and eco-conscious alternative to electric pumps, manual water pumps play a vital role in water conservation and accessibility.

Types of Manual Water Pumps

Manual water pumps come in various types, including shallow well, deep well, and hand-operated models. Each design suits different water extraction needs and well depths effectively.

Shallow Well Manual Pumps

Shallow well manual pumps are designed for wells with water at depths of up to 25 feet. These pumps are ideal for small-scale water needs, such as household use or irrigation. They typically feature a simple, compact design that allows for easy installation and operation. The pump operates by creating suction through a piston-driven mechanism, drawing water from the well and delivering it through a spout or hose. Shallow well manual pumps are cost-effective and require minimal maintenance, making them a practical choice for those seeking a reliable water supply without electricity. Their portability and ease of use also make them suitable for temporary or emergency situations. Overall, shallow well manual pumps provide a sustainable and efficient solution for accessing water in shallow wells.

Deep Well Manual Pumps

Deep well manual pumps are engineered to extract water from wells with depths exceeding 25 feet, often reaching up to 100 feet or more. These pumps are designed with a more robust mechanism to handle the increased pressure and distance, ensuring reliable water extraction. Unlike shallow well pumps, deep well manual pumps often feature a longer handle and a more efficient piston system to maintain consistent flow rates. They are ideal for households or farms with deeper water sources and require regular maintenance to ensure longevity. Despite the physical effort required, deep well manual pumps provide a sustainable and electricity-free solution for accessing water in remote or off-grid locations. Their durability and efficiency make them a valuable investment for those needing a consistent water supply from deeper wells.

Hand Operated Pumps for Wells

Hand-operated pumps are a practical solution for extracting water from wells, offering simplicity and portability. These pumps are ideal for shallow to medium-depth wells and operate through a manual handle that drives a piston to draw water upwards. Their compact design makes them easy to install and maintain, requiring minimal tools. Hand-operated pumps are highly reliable in off-grid settings, as they eliminate the need for electricity. They are also environmentally friendly, producing no emissions or noise pollution; While they require physical effort, their durability and low cost make them a popular choice for small-scale water needs. Additionally, hand-operated pumps are versatile, suitable for both residential and agricultural use, ensuring a steady water supply in remote or emergency situations. Their simplicity and effectiveness make them a valuable asset for those seeking sustainable water solutions.

Advantages of Using Manual Water Pumps

Manual water pumps are reliable, sustainable, and cost-effective, providing water without electricity. They are eco-friendly, simple to maintain, and ideal for emergencies, ensuring consistent water access in off-grid settings.

Cost-Effectiveness of Manual Pumps

Manual water pumps are highly cost-effective, offering significant savings compared to electric pumps. They require minimal initial investment and no electricity, reducing operational costs. Durable materials ensure a long lifespan, minimizing replacement expenses. Maintenance is simple and inexpensive, further lowering overall costs. These pumps are an eco-friendly, budget-friendly solution for wells, making them ideal for off-grid and remote locations where electricity is unavailable or costly. Their energy efficiency and low upkeep make them a practical choice for homeowners and communities seeking reliable water access without high expenses.

Reliability Without Electricity

Manual water pumps operate independently of electricity, making them a reliable choice for wells during power outages or in off-grid areas. Their mechanical design ensures consistent water supply without reliance on external energy sources. This independence is crucial for emergency preparedness and rural settings where electricity may be unstable or unavailable. Additionally, manual pumps are less prone to mechanical failures compared to electric models, as they have fewer components that can malfunction. Their simplicity and durability ensure long-term functionality, providing peace of mind for homeowners and communities. This reliability without electricity makes manual pumps an essential tool for sustainable and self-sufficient water management systems.

Environmental Benefits of Manual Pumps

Manual water pumps offer significant environmental benefits by eliminating the need for electricity, reducing carbon emissions, and minimizing the carbon footprint associated with water extraction. Unlike electric pumps, they do not contribute to greenhouse gas emissions, making them an eco-friendly alternative. Their simple, mechanical design reduces the risk of chemical contamination in wells, preserving water quality and protecting aquatic ecosystems. Additionally, manual pumps require minimal materials for construction and maintenance, reducing resource depletion and waste generation. By promoting sustainable water management, they align with eco-conscious practices, making them an ideal choice for environmentally responsible water extraction from wells. Their eco-friendly nature supports long-term environmental conservation efforts and sustainable living.

How to Install a Manual Water Pump

Installing a manual water pump involves selecting the right pump type, preparing the well, assembling the pump, attaching pipes, and testing for proper water flow and functionality.

Step-by-Step Installation Guide

Installing a manual water pump for a well requires careful planning and execution. First, assess the well depth and water level to choose the right pump type. Next, assemble the pump according to the manufacturer’s instructions, ensuring all components are securely fitted. Then, position the pump over the well, aligning it with the well casing. Connect the suction and discharge pipes, making sure all connections are watertight. Prime the pump by filling the cylinder with water to create suction. Test the pump by operating the handle to ensure smooth water flow. Finally, secure the pump to a stable surface and perform a final check for leaks or malfunctions. Proper installation ensures efficient and reliable water extraction from your well.

Choosing the Right Location for the Pump

Selecting the optimal location for a manual water pump is crucial for its efficiency and longevity. The pump should be placed directly over the well casing to minimize suction lift and ensure proper priming. Ensure the area is level and stable to prevent uneven wear on the pump’s components. Avoid installing the pump in low-lying areas prone to flooding or where water may collect, as this can lead to corrosion or contamination. Additionally, consider accessibility for maintenance and operation, placing the pump in an easily reachable spot. Protect the pump from extreme weather conditions by installing it under a shelter or canopy if possible. Proper placement enhances performance, reduces maintenance needs, and prolongs the pump’s lifespan, ensuring reliable water access for years to come.

Connecting the Pump to the Well

Connecting a manual water pump to a well involves securing it to the well casing with appropriate fittings to ensure a watertight seal. Attach the pump’s inlet to the casing using compatible connectors, typically screw-on fittings, to prevent leaks. Then, connect the outlet to a spigot or storage system using piping and necessary fittings. Priming the pump by adding water to initiate flow is essential for proper functioning. Ensure all connections are secure to avoid contamination and leaks. Consider the well’s depth and pump specifications to confirm compatibility. Regular maintenance, including inspections, lubrication, and replacing worn parts, will prolong the pump’s efficiency and lifespan. Following a step-by-step guide or consulting an expert can help ensure a correct and durable installation.

Maintenance and Care of Manual Water Pumps

Regular maintenance ensures optimal performance and longevity of manual water pumps. Inspect for wear, lubricate moving parts, and replace worn components to prevent corrosion and leakage issues.

Regular Maintenance Tips

Regular maintenance is crucial to ensure the longevity and efficiency of manual water pumps. Start by inspecting the pump for visible wear and tear, such as corrosion or residue buildup. Lubricate moving parts periodically to reduce friction and prevent seizing. Check the piston, cylinder, and valves for proper alignment and function. Replace any worn or damaged components immediately to avoid further damage. Additionally, clean the pump and surrounding area regularly to prevent contamination. Inspect the pipes and connections for leaks or blockages, addressing them promptly. For seasonal storage, drain the pump and protect it from harsh weather conditions. By following these tips, you can maintain your manual water pump’s performance and extend its lifespan.

- Inspect for wear and tear regularly.

- Lubricate moving parts to reduce friction.

- Replace worn or damaged components.

- Clean the pump and surrounding area.

- Check pipes and connections for leaks.

- Store properly during off-season.

Regular care ensures reliable water supply and prevents costly repairs.

Inspecting for Wear and Tear

Regular inspection of manual water pumps is essential to identify and address wear and tear promptly. Start by examining the piston, cylinder, and valves for signs of corrosion or damage. Check the pump handle and lever for looseness or cracks, as these can compromise efficiency. Look for leaks around connections and seals, which may indicate worn gaskets or O-rings. Inspect the pipes for mineral buildup or blockages that could restrict water flow. Pay attention to unusual noises or vibrations during operation, as these may signal misaligned parts or excessive friction. Use a visual checklist to ensure all components are in good condition. Inspections should be done monthly or after heavy use to prevent minor issues from becoming major problems. Early detection of wear and tear ensures smooth operation and extends the pump’s lifespan.

- Examine piston, cylinder, and valves for corrosion.

- Check handle and lever for looseness or cracks.

- Inspect pipes for mineral buildup or blockages.

- Listen for unusual noises or vibrations.

- Use a visual checklist for thorough inspection.

Regular inspections help maintain efficiency and prevent costly repairs.

Storing the Pump During Off-Season

Proper storage of a manual water pump during the off-season is crucial to maintain its functionality and longevity. Start by thoroughly cleaning the pump to remove dirt, grime, and mineral deposits that may have accumulated. Disassemble the pump to clean hard-to-reach areas, ensuring all parts are dry before reassembly. Apply a water-resistant lubricant to moving parts, such as the piston and valves, to prevent rust and corrosion; Drain all water from the pump and pipes to avoid freezing damage during colder months. Store the pump in a dry, protected location like a shed or garage, away from direct sunlight and moisture. Cover the pump with a tarp or plastic cover to shield it from dust and pests. Before storing, label any disassembled parts for easy reassembly when the pump is needed again. Regular inspection before storage ensures the pump remains in good condition for future use.

- Clean the pump thoroughly, including disassembled parts.

- Apply water-resistant lubricant to moving components.

- Drain all water to prevent freezing and damage.

- Store in a dry, protected area like a shed or garage.

- Cover the pump to protect from dust and pests.

- Label disassembled parts for easy reassembly.

Proper storage ensures the pump remains functional and ready for use when needed.

Troubleshooting Common Issues

Identify and address issues like faulty connections, blockages, or worn parts promptly to ensure optimal pump performance and prevent further damage or water supply disruptions.

Diagnosing Pump Failure

Diagnosing pump failure involves identifying the root cause of malfunction. Common signs include low water pressure, unusual noises, or the pump not starting. First, check the power supply to ensure it’s functioning correctly. For manual pumps, inspect the handle and piston for wear or damage. Look for blockages in the intake or discharge pipes, which can restrict water flow. Corrosion or mineral buildup might also impede performance. Additionally, examine the valve seats and gaskets for leaks or deterioration. If the pump is electric, verify the circuit breaker and wiring connections. Testing the pressure switch and control box can reveal electrical issues. Regular maintenance, such as lubricating moving parts and replacing worn components, can prevent unexpected failures. Accurate diagnosis ensures targeted repairs, extending the pump’s lifespan and reliability.

Fixing Leaks and Corrosion

Fixing leaks and corrosion in manual water pumps requires prompt attention to prevent further damage. Start by identifying the source of the leak, which could be from worn O-rings, gaskets, or corroded pipes. Replace damaged seals or gaskets with compatible materials, ensuring they are properly seated. For corrosion, use a wire brush to remove rust from metal surfaces, then apply a rust-inhibiting coating or paint. Inspect and clean pipe interiors to eliminate residue or mineral buildup, which can restrict water flow. Lubricate moving parts to reduce friction and prevent future wear. Regularly inspecting the pump and addressing issues early can extend its lifespan and maintain efficiency. Proper maintenance not only saves time but also ensures a consistent water supply from your well.

Addressing Low Water Pressure

Low water pressure in manual well pumps can often be resolved by checking the pump’s setup and surrounding conditions. First, ensure the pump is correctly installed and aligned with the well’s water level. If the pump is too far from the water source, it may struggle to draw water efficiently. Inspect the pipes for blockages, such as mineral buildup or debris, and clean them thoroughly. Worn or damaged valves and gaskets can also reduce pressure; replacing these components can restore performance. Additionally, verify that the pump is appropriate for the well’s depth and water volume. If the issue persists, consider adjusting the pump’s stroke length or upgrading to a model with higher flow capacity. Regular maintenance and proper sizing are key to maintaining consistent water pressure.

Manual water pumps for wells are reliable, cost-effective, and eco-friendly solutions for accessing water. They are ideal for shallow or deep wells, offering sustainable water access in off-grid and emergency scenarios.

Final Thoughts on Manual Water Pumps

Manual water pumps are a reliable and sustainable solution for wells, offering cost-effective and eco-friendly water access. They are ideal for both shallow and deep wells, providing a practical alternative to electric pumps, especially in off-grid locations or during power outages. These pumps require minimal maintenance and are durable, making them a valuable investment for long-term water supply needs. With their simplicity and effectiveness, manual pumps are a resilient choice for ensuring consistent water availability, making them an excellent option for homesteaders and those seeking self-sufficiency.

Recommendations for Future Use

For future use, consider investing in a high-quality manual water pump designed for your well’s specific depth and water needs. Regular maintenance, such as lubricating moving parts and inspecting for corrosion, will ensure longevity. Choose pumps with durable materials like stainless steel or brass to withstand harsh conditions. For deeper wells, opt for heavy-duty models or consider combining manual and solar-powered systems for efficiency. Always follow installation guidelines to ensure proper function and safety. Storing the pump correctly during off-season use will prevent damage and extend its lifespan. Additionally, explore anti-corrosion treatments and adjustable handles for improved performance. By selecting the right pump and maintaining it well, you can enjoy a reliable water supply for years to come.